Complex material handling task in a stainless steel plant

Braun Maschinenfabrik ("Braun") has supplied a complete abrasive cut-off machine for hot cutting of radially forged bars at a stainless steel plant in Bolzano, Italy. To integrate the machine in the forging line, Braun had to completely review the material handling process and installed 68 geared motors from WEG subsidiary Watt Drive on the implemented, fully automated conveyor solution.

Set up in 1848, Braun is a family-owned business which is currently centred on three fields: hydraulic steelwork, steel cutting and grinding machines, and concrete cutting and drilling machines. The company, whose headquarters are in Vöcklabruck, Austria, is one of the leading international manufacturers of state-of-the-art high-performance abrasive cut-off machines for cold and hot cutting, and high-pressure grinding machines for steel and non-ferrous metals. Customised material handling and automation systems, together with professional design engineering and comprehensive after-sales support complete the service package for the steel industry.

To drive the various units of the specially developed material handling system, which Braun implemented together with a TS 12 W type abrasive cut-off machine in the stainless steel mill - operated by the Acciaierie Valbruna S.p.a. ("Valbruna") Company in Bolzano - the firm installed various Watt Drive geared motors.

Tricky handling task

The abrasive cut-off machine in Bolzano was integrated by Braun in an existing forging line. Its task is to cut off the ends of the hot forged parts upon completion of the forging process. Previously, finished forged pieces 2.5 to 5.5 m in length were unloaded by the forge manipulator, transferred onto a roller table running parallel to the system, and then ejected as single steel bars. Longer forged pieces between 5 and 13 m in length were grasped by a simple device behind the manipulator and pushed out using the manipulator.

|

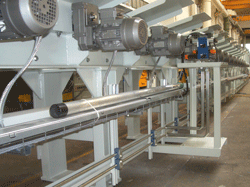

| Figure 1: The TS 12 W chop-stroke abrasive cut-off machine with horizontal separator provides efficient use of the cut-off wheel on narrow bar positions like those for this project |

One challenge for the new design of the material handling system was the limited transfer height of 0.5 m for the forge manipulator, because the roller table on the abrasive cut-off machine was substantially higher, at 1.09 m. The aim here was hence to move the forged pieces from both the unloading positions onto a single roller table line at the same height as the table at the abrasive cut-off machine.

"The compact, modular design of the Watt Drive geared motors enable us to deal with many new and above all complex tasks in the field of material handling for our high-performance abrasive cut-off and surface grinding machines", said Stefan Purrer, the head construction and project engineer for steel cutting and grinding machines at Braun.

Two paths, one goal

Several new conveyor system designs were required to implement the ambitious handling process. Firstly, the 2.5 to 5 m long forged pieces are now fully automatically moved on by a material transfer device consisting of four transport carriages from the unloading roller table to the height-adjustable roller table located 3.5 m away, or placed in one of five buffer positions.

The larger forged pieces 5 to 13 m long are now fully automatically taken out of the forge manipulator by a material transfer unit applying power and guide rollers and placed continuously on the height-adjustable roller table. The locking movement is provided by hydraulic cylinders with synchronised controls and the conveyor rollers are driven electromechanically. The latter drive systems consist of two Watt K75 type helical-bevel geared motors with power ratings of 3 kW. The geared motors feature protection class IP55 and provide a reduction ratio of i=51.02 with an output speed of 28 rpm and an output torque of 1,012 Nm.

|

| Figure 2: In all, 59 identical Watt A46 type shaft-mounted geared motors drive various roller tables in the abrasive cut-off machine; here, we can see assembly of a roller table prior to delivery |

Compensation of the height difference

The height-adjustable roller table, which is about 11.5 m long, removes the shorter forged pieces from the transport carriages using a lifting movement, featuring electromechanical onward movement and lifting movement using hydraulic cylinders. It picks the longer forged pieces up directly from the drawing unit. All the forged pieces are then moved by the height-adjustable roller table from the outlet height of 0.5 to 1.09 m, the level of the roller table at the abrasive cut-off machine.

The materials are carried by 17 individually electromechanically driven rollers. There, and on the cut-off machine feed and outlet roller tables as a whole, 59 identical Watt A46 type shaft-mounted geared motors with a power rating of 0.75 kW each are used, two of which have incremental encoders (1,024 HTL). With an output torque of 106 Nm and a reduction ratio of i=20.86, the geared motors run at a speed of 68 rpm. Due to the large amounts of heat generated during hot cutting, the drives are specially designed to operate in surrounding temperatures of up to +60°C and are also fitted with a temperature control (bimetal switch).

The lifting movement of the height-adjustable roller table is also provided (very economically) via an electromechanical system powered by a Watt F131 type parallel shaft geared motor with a power rating of 15 kW. The drive system features a spring-loaded brake (holding brake) with a braking torque of 100 Nm and through the reduction ratio of i=76.05 selected, it produces an output torque of 7,462 Nm.

"The automation technology for the synchronisation of these three interrelated material handling units, together with the interface with the existing radial forging machine, constituted a particular challenge in this project", explained Purrer. "We really appreciate Watt Drive's expert support and high levels of supplier reliability. Together with their short delivery times, these also contribute to our ability to deal with such ambitious projects efficiently. Over and above that, we can guarantee the highest levels of availability for our customers thanks to the use of high-quality Watt products".

|

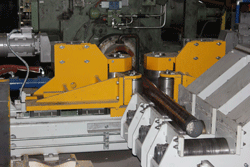

| Figure 3: Two Watt geared motors are used to ensure that the larger forged pieces from the material drawing unit are fully automatically moved from the forge manipulator onto the height-adjustable roller table |

Finally on to the cooling bed

Upon completion of the abrasive cutting procedure, the forged pieces are taken out of the machine and moved on for cooling to the chain conveyor or the chain vat. The chain conveyor drive systems, two F111 type parallel shaft geared motors with a power rating of 3 kW each, are designed to operate in surrounding temperatures of up to +60°C, and are fitted with a temperature control (bimetal switch). For gradual cooling of the forged pieces, the geared motors have a reduction ratio of i=207.08, with a speed of just 7 rpm. The space-saving modular Watt geared motors enable very fine speed adjustments, even at low speeds. For example, the two six-pole F137 type parallel shaft geared motors of the chain vat swivel drive with a power rating of 1.5 kW run considerably more slowly, at 1.4 rpm. To prevent the forged pieces from falling, the motors are fitted with brakes giving a braking torque level of 20 Nm.