WEG presents new flexible and efficient geared motors

WEG, a leading global manufacturer of motor and drive technology, is launching the WG20, a new range of highly versatile modular geared motors that offer worldwide interchangeability and up to 96% energy efficiency across a wide range of industrial applications requiring precise and reliable power transmission. The new geared motor will enable users to increase the energy efficiency of systems in their plants significantly, reducing associated energy costs.

Developed in cooperation with the company’s subsidiary – gear technology specialist Watt Drive - the WG20 comes in standardised mounting dimensions to suit both new and existing drive systems, ensuring ease-of-installation and flexibility when retrofitting. It is designed to cover virtually all international supply voltages thanks to internal voltage switching, which makes it easily interchangeable.

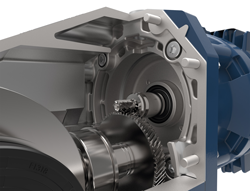

Available in energy efficiency classes IE2 and IE3, the motors feature an advanced design, with the pinion directly mounted on to the motor shaft resulting in a two-stage gear unit (in place of the commonly used three-stage unit). Fewer stages means reduced friction, which translates into lower power and heat dissipation and thus more efficiency. Additionally, the improved gear geometry featuring optimised gear teeth and high quality ground gear parts ensure low-loss power transfer and low noise levels, along with reliable performance and extended service life.

|

| Figure 1: The intelligent pinion concept allows the WG20 geared motors to cover a wide range of applications with a two-stage configuration |

“The WG20 - the first WEG-branded geared motor product line – brings together Watt Drive’s high R&D and manufacturing competence and WEG’s motor expertise, which is supported by a global sales and service network,” says Norbert Reisner, Head of Geared Motor Technology at Watt Drive. “By adopting smart design and optimised production processes, we have developed a top-quality geared motor range which fulfils all requirements of modern drive systems across a wide range of industrial applications around the world.”

The compact gear unit design also has a positive impact on the required lubricant volume. The gear arrangement and the advanced housing interior allow the gear units to operate with a low oil level. The optimised oil fill level and low friction losses in turn prolong the life of the seals and extend the oil change intervals, therefore minimising time and costs associated with maintenance.

|

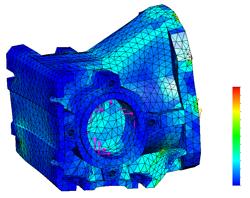

| Figure 2: The rugged pressure-cast aluminium housings developed with the aid of finite-element methods are significantly lighter than previous versions |

The WG20 is built with helical, parallel-shaft and helical bevel gear units with rugged pressure-cast aluminium housings and is suitable for most industrial applications requiring torque ratings between 50 and 600 Nm. International certifications further enhance the geared motor unit’s versatility, enabling users to operate it at 100 or 120 Hz with variable speed drives.